About welding

Terminology

This page introduces some common terms used in arc welding.

What is welding?

Welding means joining pieces by melting them into one.

The outcome is a solid object of one material.

Usually welders weld metals such as iron, steel or aluminium, but just as well you could weld e.g. plastics.

To melt the material, heat is required. There are many different methods to produce the heat: electricity, laser light, explosions etc. The most common method is arc welding.

The outcome is a solid object of one material.

Usually welders weld metals such as iron, steel or aluminium, but just as well you could weld e.g. plastics.

To melt the material, heat is required. There are many different methods to produce the heat: electricity, laser light, explosions etc. The most common method is arc welding.

What is arc welding?

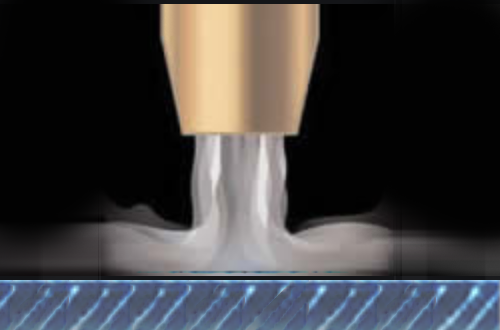

In arc welding, an electric arc creates the heat to melt and join the parts.

The welding power source provides the needed current and voltage. The voltage difference between the electrode and the base material creates the arc. Depending on your welding process, you use either direct (DC) or alternating (AC) current.

This process can be categorised into two different types: using consumable and non-consumable electrodes. The consumable electrode is a wire or a rod which melts into the weld pool.

Just a couple of examples of different processes:

- In MIG (Metal Inert Gas) and MAG (Metal Active Gas),

the welding gun delivers both the filler wire and the shielding gas. - In TIG (Tungsten Inert Gas),

the welding torch has a non-consumable tungsten electrode, and the torch also provides the inert shielding gas. - in MMA (Manual Metal Arc),

the arc forms between a metal rod (consumable electrode) and the work piece. Both the rod and the work piece surface melt to form a weld pool. - In PAW (Plasma Arc Welding),

there is an electric arc between a non-consumable electrode and an anode. They are both placed within the body of the torch. The electric arc is used to ionise the gas in the torch and create the plasma, which is then pushed through a fine bore hole in the anode to reach the work piece.

In different regions, the same processes can have different names. So MIG and MAG are also known as GMAW (Gas Metal Arc Welding), and MMA is also known as stick welding and SMAW (Shielded Metal Arc Welding).

Why do you need shielding gas in welding?

The shielding gas protects the weld area from oxygen and water vapour. Without shielding gas, oxygen and water vapour would react with the glowing metal and ruin your weld.

Why do you need a filler wire?

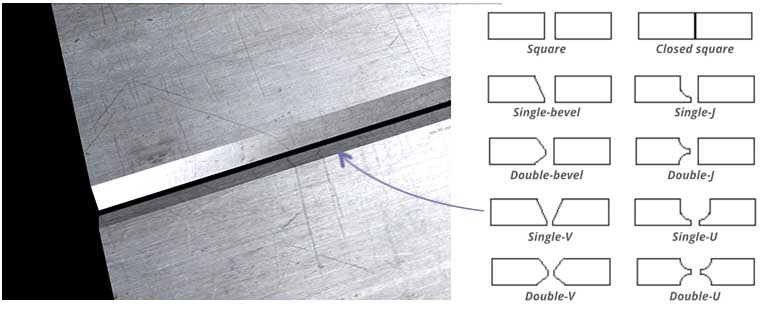

Between the metal plates to be joined, there is often a groove to fill:

a space between two close-fitting workpieces. This space is filled with the filler material.

a space between two close-fitting workpieces. This space is filled with the filler material.

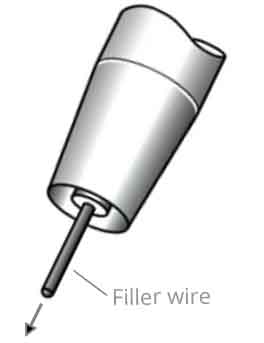

Also the filler must be of the same metal as the workpiece. The filler material comes in a metal wire.

In MIG welding, this wire serves also as the electrode that creates the welding arc.

Why is the shape of the groove important?

The groove is the space between two close-fitting workpieces.

The groove allows for better penetration of the filler material into the joint. This enhances the strength and quality of the weld joint.

The optimum shape and dimensions of the groove depend on a number of factors, including material type and thickness, welding position and welding process.

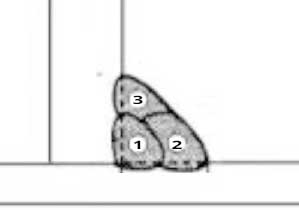

The filler material fills in the groove

This example groove is incompletely filled.

At least one more pass is required.

At least one more pass is required.

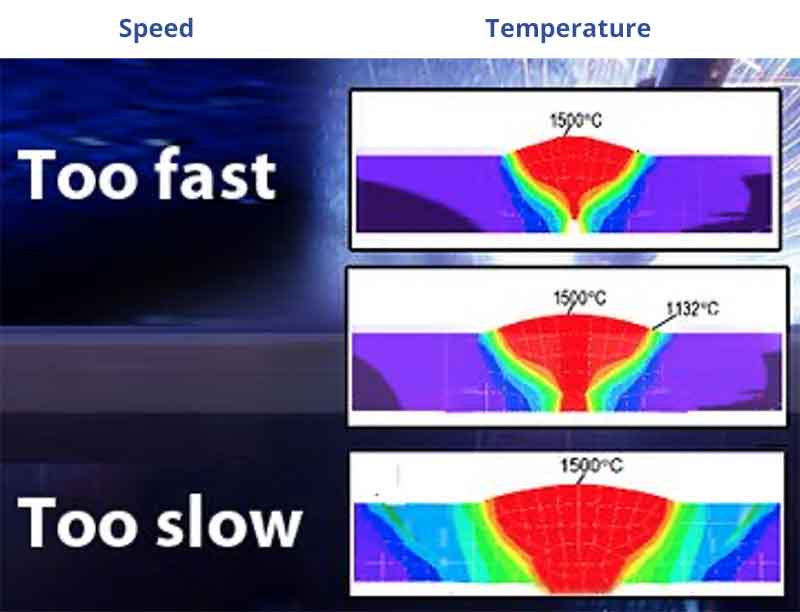

What is travel speed?

Travel speed means the speed with which you move the welding gun.

With the travel speed, you control the heat input. Too little heat does not melt the metal. Too much heat destroys the weld.

Moving your hand with a steady speed is not easy. You can practice your skills with the Welding Game.

Is welding easy?

As a welder, you must control your hand movements in many ways:

You must position the arc to follow the groove, you must keep the right travel speed and also the right distance between the electrode and the workpiece. Simultaneously, you must control the stick-out length, the arc length and the torch angle while watching how the weld pool behaves. Mastering the hand movements requires a lot of practice just as with any handicraft.

You must position the arc to follow the groove, you must keep the right travel speed and also the right distance between the electrode and the workpiece. Simultaneously, you must control the stick-out length, the arc length and the torch angle while watching how the weld pool behaves. Mastering the hand movements requires a lot of practice just as with any handicraft.

What is the difference between a welding gun, a welding torch, and an electrode holder?

Welding terminology varies in different cultures:

different terms might mean the same, and the same term might have different meanings.

different terms might mean the same, and the same term might have different meanings.

Some use the term welding gun used with MIG welding (also known as GMAW) and welding torch with TIG welding, so there are MIG guns and TIG torches. Some call all of them just torches: MIG torches or TIG torches.

In stick welding, also known as MMA and SMAW welding, you use an electrode holder, also known as stick holder.

What is stick-out length?

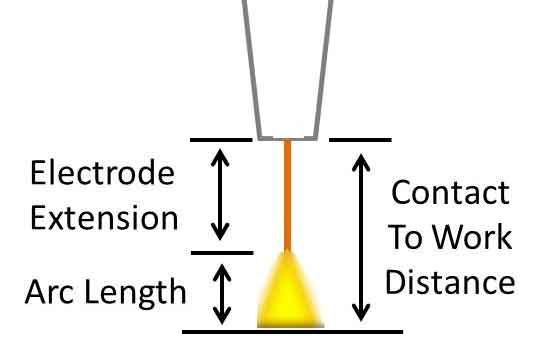

Stick-out length is the length of the wire between the MIG gun and the workpiece.

In MIG welding, the stick-out length (also known as electrode extension) is the length of the filler wire that extends past the contact tube. This is the area where preheating of the filler wire occurs. It controls the dimensions of the weld bead since the length of the filler wire extension affects the burn-off rate.

What is arc length?

Arc length is the space between the tip of the welding electrode (which in MIG welding is the wire) and the surface of the workpiece being welded.

During welding, the arc length is dynamic and can vary during the welding process as the welder moves the welding torch or electrode holder.

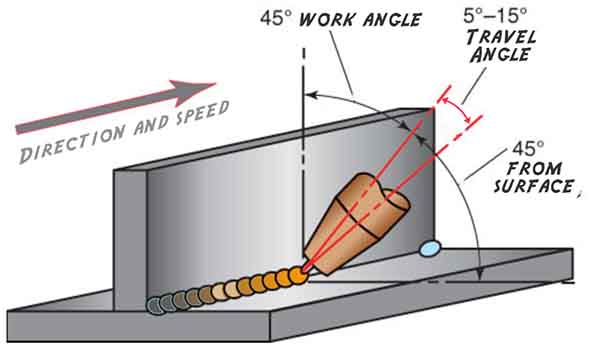

What are the torch angle, work angle and travel angle?

Welding is affected by the torch angle which is a combination of the work angle and the travel angle. The picture explains them better than words.

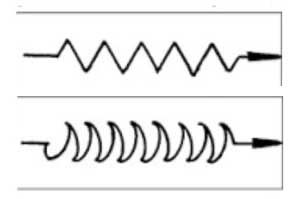

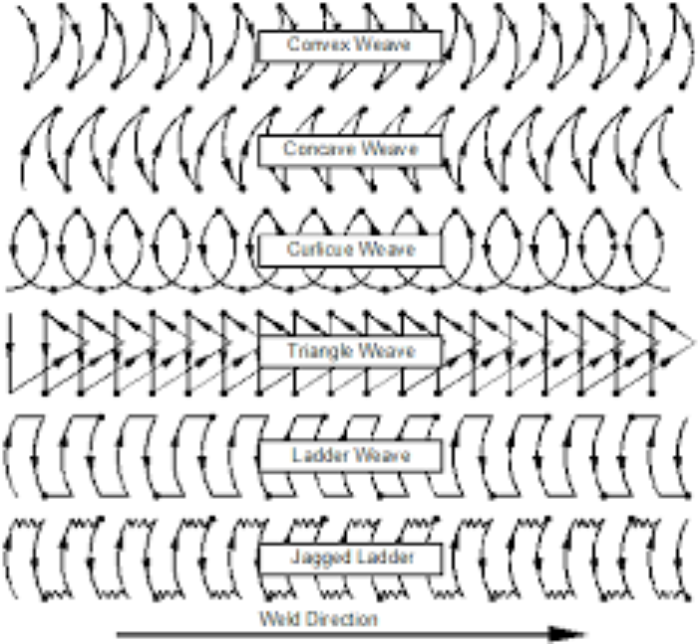

What is weaving?

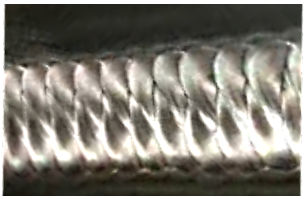

Weaving means moving the arc also sideways. That way you can fill in the whole width of the groove, with a single pass.

Different hand motions produce different weaving patterns. Great welders can be recognized by their handwriting.

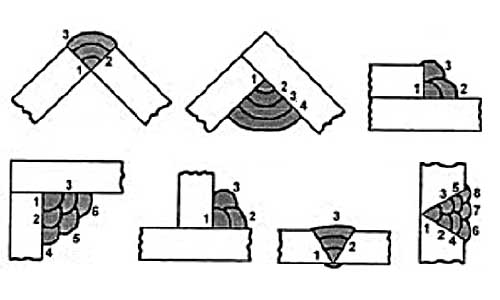

What are passes?

A weld may consist of several passes. Small welds can be completed with a single pass. Thicker welds require several layers: First weld the root pass, then add another pass, and possibly a few more. The outcome is a multi-pass weld.

What are the welding parameters?

The welding arc is shaped by many parameters of the welding device. The most fundamental settings are the Current (Ampers) and Voltage (Volts). Ampers x Volts = Power that heats the metal.

In GMAW / MIG / MAG welding, also the Wire Feed Speed is critical.

Depending on the welding process, you could be adjusting also numerous other parameters, such as pulse frequencies or alternating power levels.

Moreover, there could be special parameters to start and to end the weld smoothly.

In some advanced devices, you might only need to adjust one parameter – typically the Wire Feed Speed – and the other ones are adjusted automatically along. However, to calculate the optimum parameter combination, the device must be pre-configured so it knows what you are welding. Before starting the work, you would input e.g. the workpiece material, the plate thickness, the joint type and the filler wire diameter.

In GMAW / MIG / MAG welding, also the Wire Feed Speed is critical.

Depending on the welding process, you could be adjusting also numerous other parameters, such as pulse frequencies or alternating power levels.

Moreover, there could be special parameters to start and to end the weld smoothly.

In some advanced devices, you might only need to adjust one parameter – typically the Wire Feed Speed – and the other ones are adjusted automatically along. However, to calculate the optimum parameter combination, the device must be pre-configured so it knows what you are welding. Before starting the work, you would input e.g. the workpiece material, the plate thickness, the joint type and the filler wire diameter.

What is WPS?

WPS means Welding Procedure Specification

In professional welding, you are often required to follow a specific WPS for the given task. A WPS is always based on laboratory tests: which parameters and welding techniques are required to produce a perfect weld.

Each WPS is tailored for a specific task, taking into account the given material, plate thickness, joint type, groove type, welding position, wire diameter, shielding gas and so on.

In some welding devices, you may use digital WPS: the recommended settings are downloaded to your device, so the parameters are set automatically and the risk of human errors is reduced.